Environmentally friendly:

Laser cleaning is a method that neither pollutes the environment nor uses hazardous cleaning agents, making it environmentally friendly.

Efficient operation:

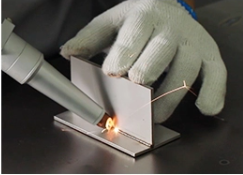

Fiber laser technology and non-contact cleaning method have minimal impact on the materials being treated, enabling fast processing and saving time in pre- and post-processing operations.

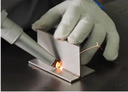

High-quality and precise results:

The powerful laser source ensures stable beam output, resulting in consistent cleaning quality and robust, smooth welds that are three to four times faster than conventional TIG or MIG welding.

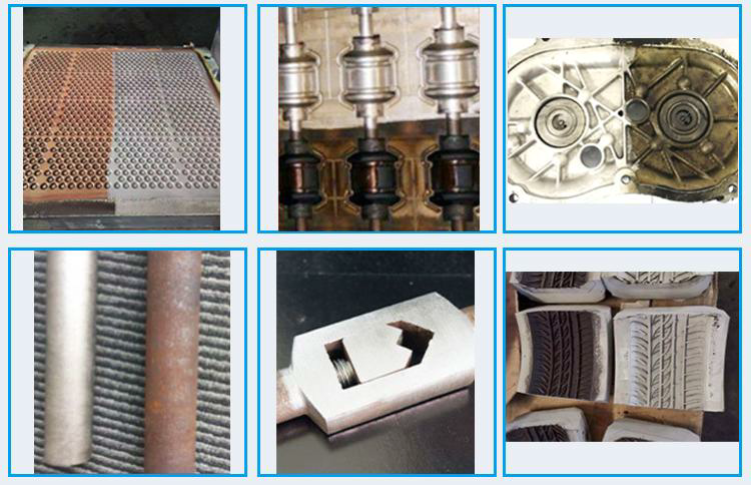

Versatility:

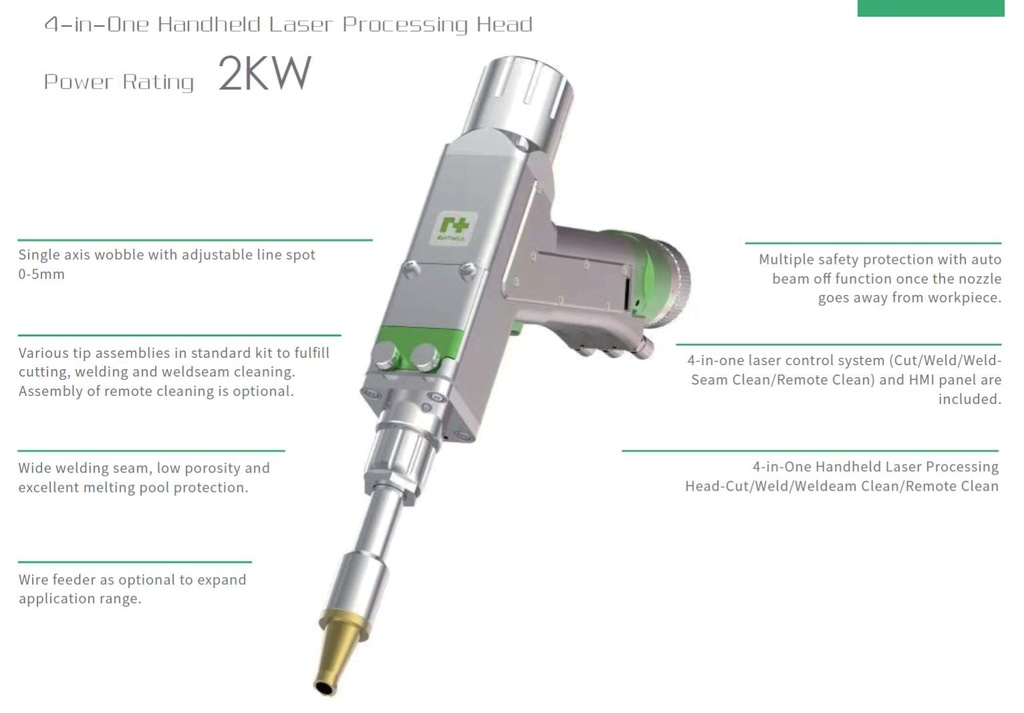

Multifunctional operations enable use for various material processing requirements in various industries such as aerospace, automotive, military and defense, power generation, nuclear facilities, and maintenance and repair facilities.

Usability:

The compact portable case contains an integrated water cooler, a long fiber optic cable and an ergonomic laser gun with interchangeable nozzles for cleaning and welding operations.

Maintenance-free:

The laser source has a long service life and laser cleaning does not require any consumables, making maintenance easy and cost-effective.

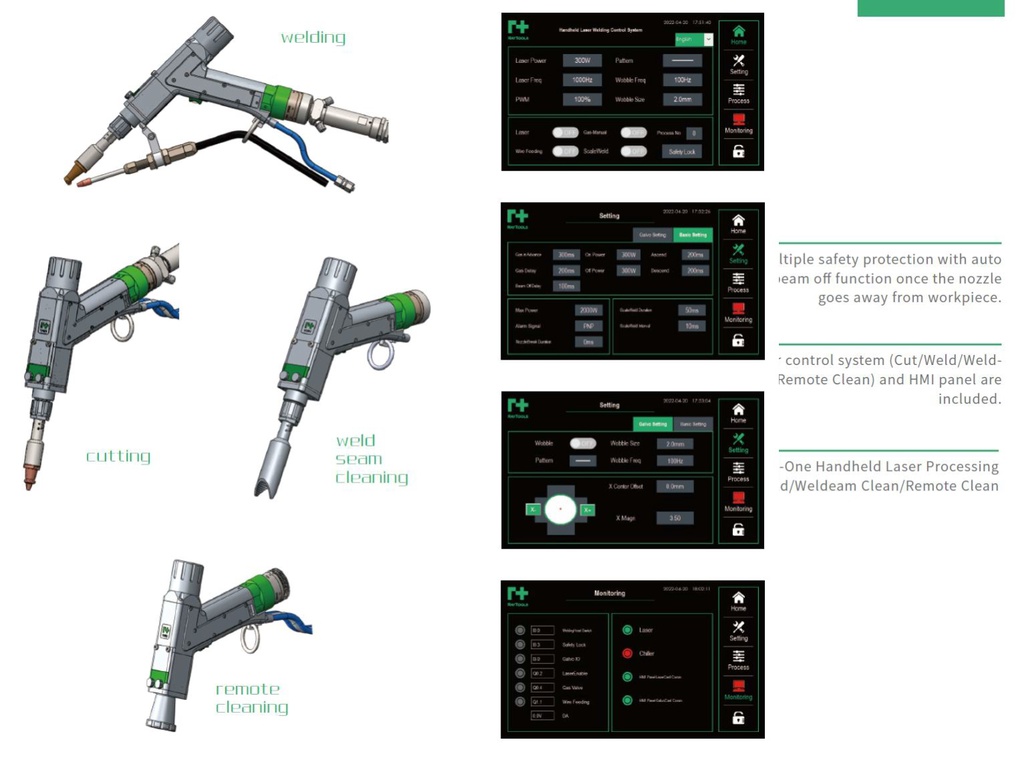

User-friendly HMI:

The Smart Control Panel has built-in preset parameters for different materials and thicknesses as well as easily switchable operations, which shortens the learning curve and simplifies use.