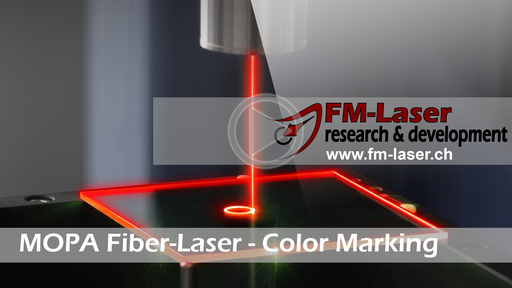

MOPA-Laser: Color Marking

Was ist ein MOPA-Laser?

MOPA color laser marking is a new type of laser marking process. Currently, this technology can only mark color samples on stainless steel, chrome, titanium and a few other metal materials. A MOPA color laser marking machine can change the color of the surface layer of the material by adjusting the laser beam while coloring the stainless steel material to create decorative effects with different colors and add value to the product.

There are many questions about MOPA laser engraving. How many colors can be engraved? can engrave deeply? What is the difference between a MOPA laser and other laser technologies? What are the pros and cons of MOPA laser technology? In this blog, FM-Laser gives an answer to these questions.

Physic

Fiber laser marking is a technology that oxidizes the first layers of a metal surface using a laser-induced high-temperature process.

Materials

With the MOPA laser, you can also mark plastics higher-contrast and more legible results, mark (anodised) aluminum in black or create reproducible colours on steel. In addition, you can produce qualitatively equivalent markings with the MOPA laser partially faster than with the conventional fiber laser. With the MOPA laser, the pulse durations can be set to predefined values. The MOPA laser is one of the most flexible lasers on the market and can be used for many applications: With respect to pulse duration, it can simulate the properties of conventional fiber lasers (relatively long pulses) and those of classical solid state lasers (relatively short pulses) such as Nd:YAG or Nd:YVO4 (vanadate).

Speed

When engraving with color effects, the laser machine must mark with minimal hatching effect at high frequencies. This makes the engraving resolution high, but at the same time makes the speed engraving slower compared to other laser engraving technologies. In fact, this technology was designed to mark a few parts per day. It is not designed to mark many parts per minute.For these reasons, this technology is more likely to produce small batches than can engrave hundreds or thousands of parts in a day.

Advantages of a MOPA Laser

For short pulses and lower pulse energy, the material is e.g. heated less and the area of the heat affected zone (HAZ) is reduced. This results in less energy consumption and more advantages and possibilities for laser marking metals and plastics:

Less burning/melting in the edge area of metal engravings

Less heat development during annealing markings on metal, which leads to a better corrosion behavior

Less energy consumption due to shorter pulses

Creation of reproducible annealing colors on stainless steel

Black marking of anodized aluminum

Controlled melting of plastics

Less foaming with plastics

More homogeneous and sometimes higher-contrast markings on some plastics

Our Offering

FM-Laser specializes in this technology. We offer our customers the option of color coding metals using MOPA laser technology. From individual pieces to small series, we can carry out your orders with high quality, reliability and short delivery times.

Contact us today for a no-obligation consultation.